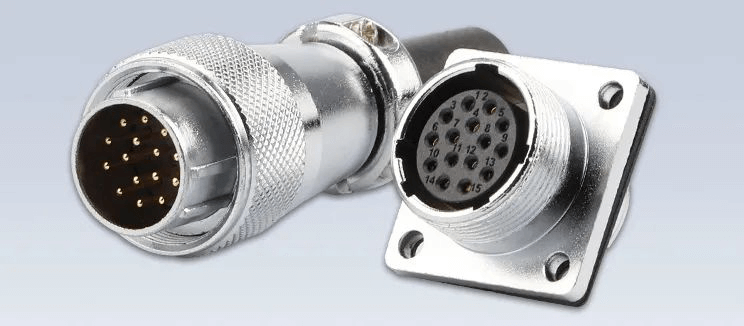

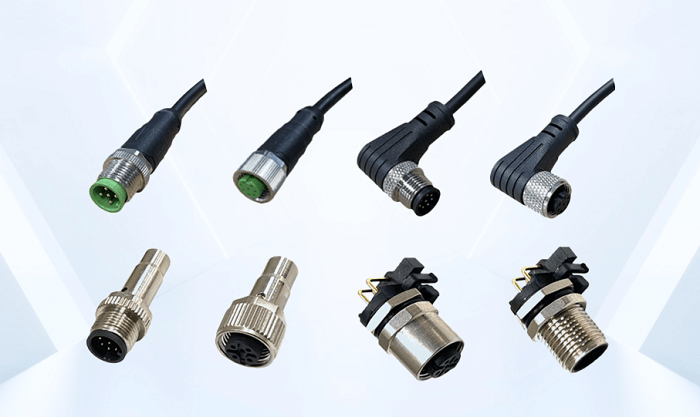

In the field of industrial automation, the waterproof function of the connector is the key to ensure the reliable operation of equipment. Among them is the M12 connector with its excellent waterproof performance and favored, Electronic Valley will be from the role of waterproof sealing ring, material, structure and performance testing and other levels, the M12 connector analysis to understand its realization of IP67 level and above the mystery of waterproof performance, to provide users with connector selection reference.

As industrial automation equipment often need to work in extreme environments, such as high temperature, high pressure, humidity and dust environment. These factors put forward very high requirements on the waterproof performance of the connector. The waterproof performance of the connector is the basis for ensuring the stable operation of the equipment, which can avoid the production stagnation caused by connector failure, thus reducing the operating costs of the enterprise.

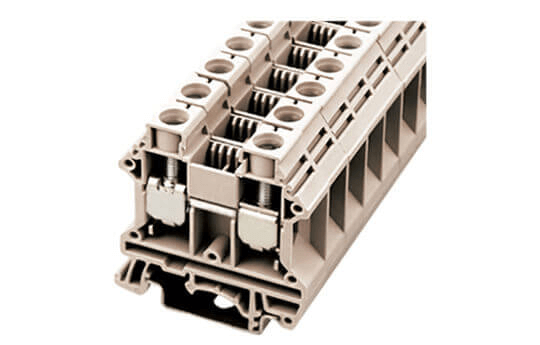

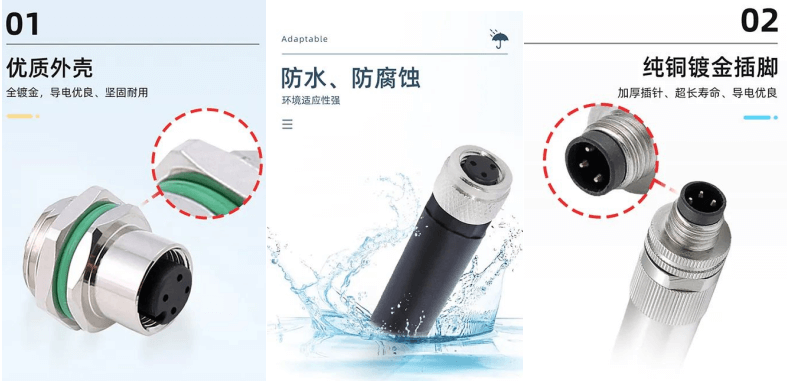

The waterproof function of M12 connector mainly relies on its built-in waterproof sealing ring, which can effectively prevent water from intruding into the connector. The waterproof sealing ring can be divided into rubber, PTFE, PU and other types according to different materials.

- Rubber seals are the most commonly used seals in M12 connectors, with excellent elasticity and durability, but their performance may be affected under extreme temperatures;

- Polytetrafluoroethylene (PTFE) seals Excellent resistance to high and low temperatures and corrosion, suitable for a variety of harsh environments, but at a relatively high cost;

- Polyurethane (PU) seals PU seals have good elasticity and weather resistance and are suitable for outdoor use, but their high temperature resistance is relatively weak.

In addition to the difference in material selection, the seal design is reasonable and whether the installation process is standardized, also affects the M12 connector waterproof performance. Derived from a variety of M12 connector waterproof performance testing methods, such as the common water pressure test and water immersion test. Hydrostatic test is a key method to assess the waterproof performance of M12 connectors, through the simulation of the actual use of the water pressure in the environment to check its waterproof performance; while the water immersion test is the connector immersed in water for a certain period of time, to observe its waterproof performance. In addition, for M12 connector reliability testing such as aging test, vibration test and so on.

Since its introduction in 1985, the M12 connector to replace the previous engineers to pull the wire directly or repeatedly replace the connector habits, growing into the field of industrial automation preferred interconnection program. E-Valley’s M12 connectors are recognized for their excellent performance and durability in the harshest environments, helping China’s industrial automation sector to thrive.