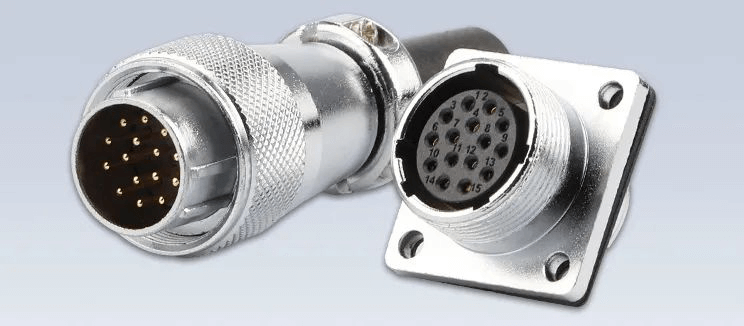

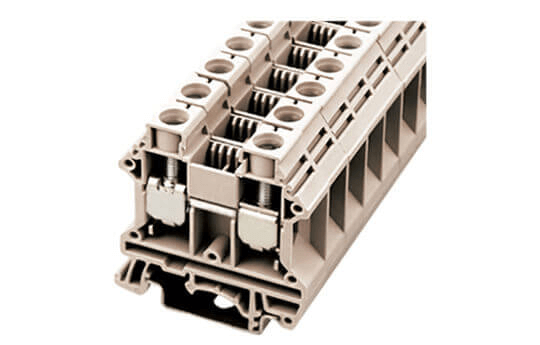

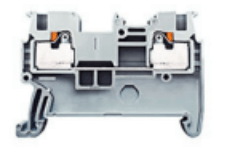

The rail type terminals, as the name suggests, is a need to use with the rail for the use of terminals, in order to facilitate the connection of wires, it is inside a section of the metal sealed in the insulating plastic inside the two ends have holes can be inserted into the wires, there are screws used to fasten or loosen. In practice, such as two wires, sometimes need to be connected and sometimes need to be disconnected, then you can use the terminal to connect them, and can be disconnected at any time, without having to weld them up or twisted together, suitable for a variety of special scenarios that require flexible switching.

Technical parameters

Wire cross-section: usually support a variety of wire cross-section, such as 0.14 to 25 mm2, depending on the product model.

Rated voltage: generally 600V.

Rated current: Depending on the model, the rated current can reach 20A to 32A.

Material: Insulation is usually PA (polyamide) with UL94 V-0 flame retardant rating.

Connection: CAGE CLAMP® connection technology or screw fixing.

Common types

Screw type

Vibration-proof structure design prevents wire loosening caused by vibration, applicable to a wide range of wire diameters, the most commonly used specifications in the market today.

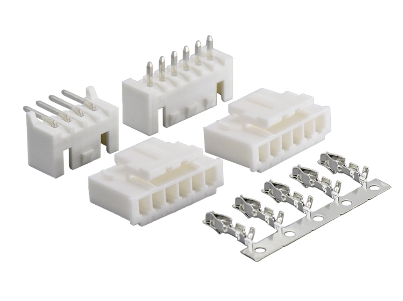

Shrapnel Type

One-piece molded stainless steel shrapnel design with embossed copper conductive plate ensures stable clamping force and excellent conductivity in vibration environments.

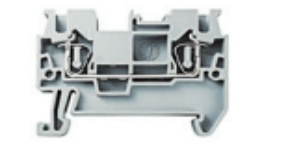

Plug-in type

Plugs directly into the wiring without the use of tools, dramatically reducing wiring installation time.

Application scenarios

Industrial control cabinets: Quick connection of PLC I/O modules, reducing control cabinet wiring time (e.g. Phoenix PT series).

Photovoltaic systems: 4mm2 PV-specific terminals with 1500V DC resistance with anti-touch protection (e.g. Wago 2000 series).

Building power distribution: three-level wiring capability (e.g., incoming, outgoing, jumper) with support for busbar integration.

Transportation: vibration-resistant design, passes EN 61373 shock vibration test.

In practice, rail type terminal blocks are mostly used for efficient connection of modular components with multiple conductors, which can significantly improve the reliability and maintenance efficiency of the electrical system, and are widely used in the industrial and power distribution fields for their easy installation and expandability, and are one of the cornerstone components of modern electrical design.