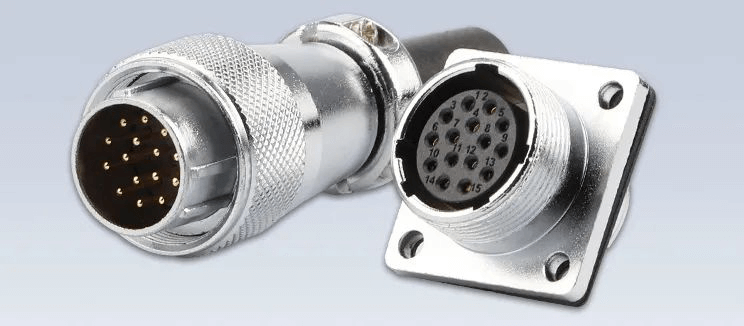

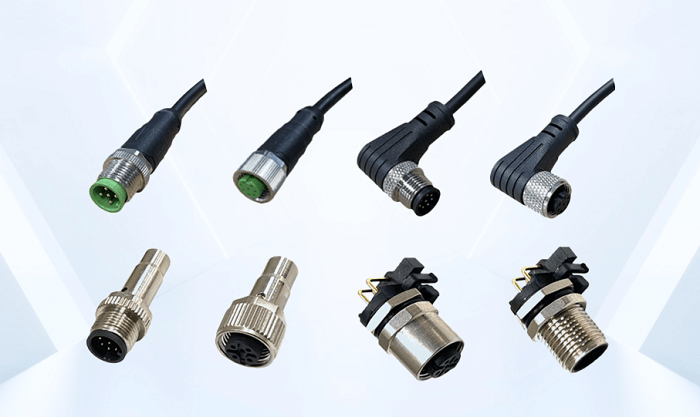

M12 interface connector with its diameter of 12 mm named and excellent connection and efficient transmission performance, is widely used in industrial automation, robotics, medical equipment and automotive electronics and other fields, and straight and elbow as the most intuitive difference between the M12 connector, the following will be analyzed in the actual use of what is different.

1. Structural differences

The same literal meaning, straight M12 connector shell and terminals are straight shape, suitable for spacious, easy to install occasions. And elbow M12 connector shell and terminals are curved shape, can effectively reduce the bending radius of the cable, suitable for small space, installation difficulties in the occasion.

2. Performance differences

Straight M12 connector compared to the elbow structure in the transmission process, the signal attenuation is small, suitable for long-distance transmission, elbow M12 connector, on the contrary, the signal attenuation is larger, more used in short-distance transmission. Wanlian-Electronics Valley has a large number of connector models in stock, according to the actual need to choose.

3. Application

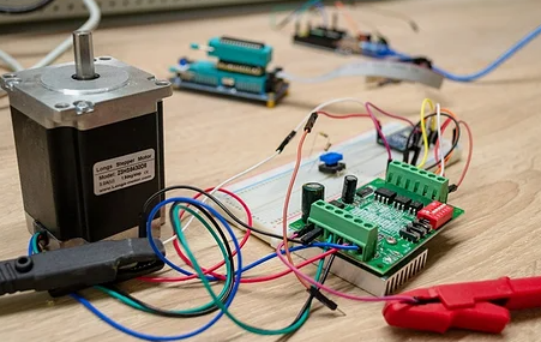

Straight connector is the most common type of M12 interface connector, suitable for straight wiring, which is characterized by simple structural design, convenient installation; stable transmission performance, excellent interference immunity; for high-speed and high-frequency data transmission, such as pipelines, cables and so on. The elbow M12 connector can be adjusted according to the wiring needs of the connection angle; has a certain tensile strength, improve the stability of the connection; for wiring relatively complex scenes, and the latter is mostly used in short-distance signaling scenarios such as servo motors, sensors.

M12 connector straight and elbow in the structure, performance and application of certain differences. In practice, according to the installation environment of the equipment, transmission distance and signal quality and other factors, select the appropriate connector form, you can ensure the normal operation of the equipment and the stable transmission of signals. Of course, in addition to the straight head elbow, such as the difference in coding, whether with shielding, assembly / molding and other differences, is also one of the keys to selecting the M12 connector, welcome to comment and add.