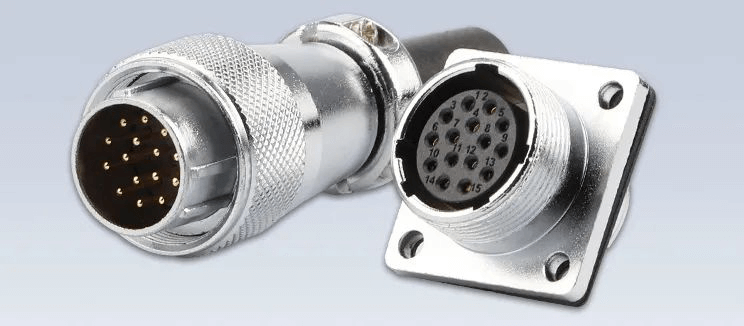

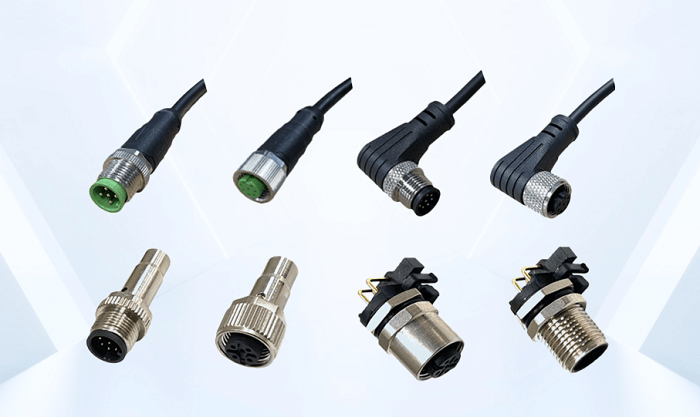

In today’s industrial field and many application scenarios in complex environments, the performance of the connector iscrucial.M12 connector has become the first choice for connection of many devices due to its excellent waterproof performance. It is widely used in automated production lines, industrial robots, outdoor instrumentation, transportation and many other fields. Especially in various outdoor scenarios, no matter in the humid seaside environment, or in the field which often encounters rain, M12 connectors can provide reliable connections for instruments to ensure accurate data collection and transmission.

M12 connectors are available in a variety of waterproof ratings, with IP68 and IP69K being the most common highly waterproof and widely used ratings. The IP code is the international designation used to identify the level of protection, followed by two digits, each with a specific meaning, and there are differences in specific protection details and application scenarios.

The first digit “6” in IP68 and IP69K indicates complete protection against foreign objects and complete protection against the ingress of dust. This means that the M12 connector is structurally designed to effectively block dust particles, so that even in dusty industrial environments or windy outdoor areas, no dust will enter the connector and affect its performance. The second number “8” indicates that the connector can be used in fairly deep water for a certain period of time or under water pressure, and still ensure that no damage will be caused by submersion. Specifically, it can be immersed in 1 meter of water for 30 minutes and still work properly. And “9K” means that the connector can be at a high temperature of 80 ℃, 100bar high pressure, at an angle of 140 ° for water jet test, and can work without affecting its performance.

In terms of protection, the IP69K is significantly more watertight than IP68, which is designed for general immersion in water, whereas the IP69K is designed to cope with extreme water washout at high temperatures and pressures. In terms of construction, IP69K rated M12 connectors are typically made of stronger, better sealed materials and construction. Their seals may have higher resistance to high temperatures and pressures to withstand the rigors of testing. In terms of cost, IP69K rated connectors are relatively expensive due to the need to meet higher protection requirements, and more stringent production processes and material selection.

In practical applications, users need to choose the corresponding waterproof M12 connector according to the specific use environment and needs, depending on whether the waterproof scenarios to ensure the stable operation of the equipment and the reliability of the connection. Whether IP68 or IP69K grade M12 connectors, in their respective fields of application for industrial production and the normal operation of various types of equipment to provide a strong guarantee. With the continuous development of the industry and the improvement of the performance requirements of the equipment, these two waterproof grade M12 connectors will also play an important role in more areas to promote the progress and development of the industry.