Recognize the M12 connector wire sequence standard, build a solid equipment stable operation line of defense

As a widely used connecting device in the industrial field, M12 connectors are found in many key areas such as industrial automation and communication. Such as industrial automation scenarios, various types of precision production equipment, automated production lines rely on M12 connectors to achieve stable transmission of signals and power. It is like the “nerve vein” of the equipment, ensuring that each component can accurately and precisely interact with each other, thus guaranteeing the efficient and stable operation of the production line.

It is important to know that the normal operation of the M12 connector is crucial to the stable operation of equipment and systems, and the wire sequence standard is one of the core elements to ensure its normal operation. The wire order standard specifies the function and connection order of each pin in the connector, just like the traffic rules, only if all the vehicles are driven in the specified direction and order, the traffic can be smooth. Similarly, only by strictly following the wiring standards of M12 connectors can we ensure that signals and power can be accurately transmitted to the corresponding equipment ports to realize the normal communication and cooperation between equipment. Once the wiring is incorrect, just like traffic chaos, the equipment will not operate normally, and may even cause serious malfunctions.

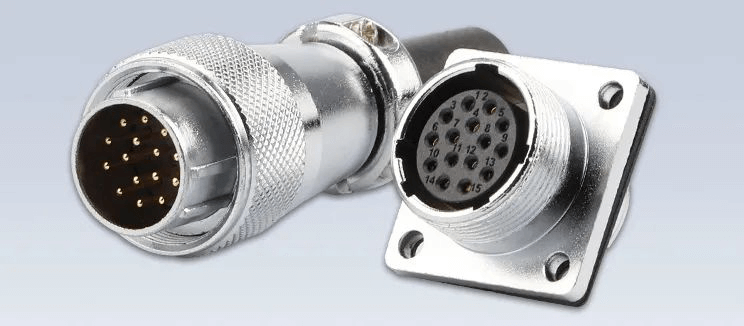

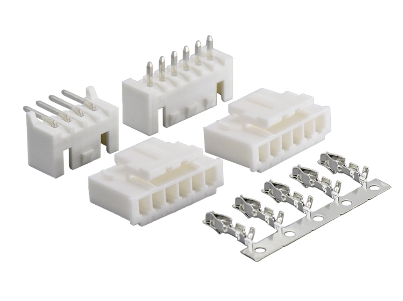

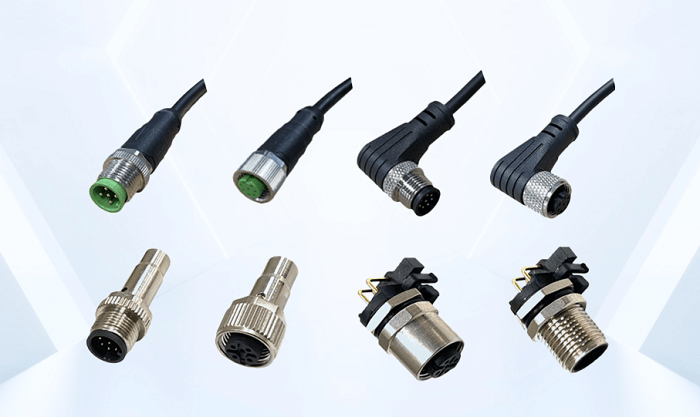

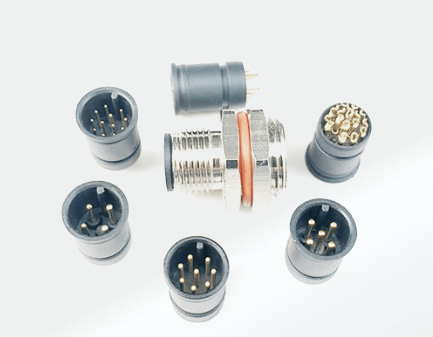

M12 connector common wiring sequence has a variety of types to meet the needs of different application scenarios. Among them, the more common is 4-pin, 5-pin, 8-pin and other different pin number of the wiring sequence.

- 4-pin M12 connector: usually 1 pin for the power positive, 2 pins for the power negative, 3 pins for the signal positive, 4 pins for the signal negative. This wire sequence design is mainly used for some simple sensor or actuator connection, to realize the basic functions of power supply and signal transmission.

- 5-pin M12 connector: on the basis of 4-pin added a pin, this pin is usually used for grounding or other special functions. For example, in some equipment with high requirements for electromagnetic compatibility, the added pin can be used as a shielding ground, effectively reducing electromagnetic interference and improving the stability of signal transmission.

- 8-pin M12 connector: It can realize multiple functions at the same time, relatively more complex, in which part of the pins are used for power transmission, part of the pins are used for signal transmission, and some pins are used for special functions or spare. For example, in the connection of industrial Ethernet, 8-pin M12 connector can realize high-speed data transmission through a specific wire sequence to meet the requirements of industrial automation control system for real-time and reliability.

In terms of installation standards, the first step is to ensure that the specifications of the connector and connecting wires are matched. Different application scenarios have different requirements for the electrical and mechanical properties of the connector, and it is necessary to select the appropriate specifications of the M12 connector and connecting wire to ensure the stability and reliability of the connection. Second, in the wiring process, we must operate in strict accordance with the wire sequence standard. Use professional tools for wire stripping, crimping and other operations to ensure that the connection between the wire and the pin is firm, to avoid the phenomenon of false connections. At the same time, attention should be paid to the correct installation and fixation of the connector to prevent the connector from loosening due to vibration and other reasons during the operation of the equipment, thus triggering wiring errors.

In addition, in the design and layout of the equipment, we should give full consideration to the M12 connector wiring convenience and operability. Reasonable planning of the connector installation location and wiring, to avoid wiring errors due to space constraints, wiring confusion and other reasons. At the same time, you can set up obvious signs near the connector, labeling the wiring sequence and connection instructions, so that operators can easily carry out wiring and inspection.

Correct wiring is a prerequisite to ensure the normal operation of the M12 connector, but also to ensure the stable operation of equipment and systems. Only correct wiring can realize the accurate transmission of signals and power, so that the equipment can work properly according to the design requirements. In the field of industrial automation, correct wiring can ensure the efficient operation of the production line, improve production efficiency, reduce the defective rate, and bring considerable economic benefits for the enterprise. In the field of communication, the correct wiring can guarantee the stability and reliability of the communication network, provide people with high-quality communication services, and promote the rapid transmission and sharing of information.

At the same time, correct wiring is also related to the safety of equipment and personnel. Avoiding electrical faults and safety hazards caused by wiring errors can effectively protect the equipment from damage and extend the service life of the equipment. More importantly, it protects the personal safety of operators and prevents injuries and deaths caused by electrical accidents. We must attach great importance to the wiring of the M12 connector, with a rigorous attitude and professional operation, to build a solid line of defense for the normal operation of the equipment.