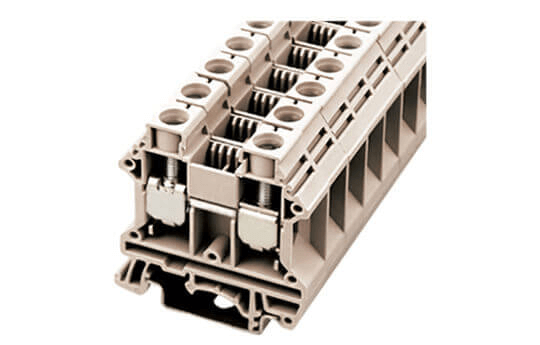

Connectors can be categorized into general connectors for commercial use and high-performance connectors designed for special industry use, also known as military connectors, aviation connectors, etc. These high-performance electronic devices can ensure the stable transmission of signals, power and data in extreme environments. These high-performance electronic devices can ensure the stable transmission of signals, power and data in extreme environments, and are an indispensable “lifeline” for modern defense equipment. Compared with ordinary commercial connectors, the core difference lies in the stringent requirements for extreme environmental adaptability, ultra-high reliability and full life cycle traceability.

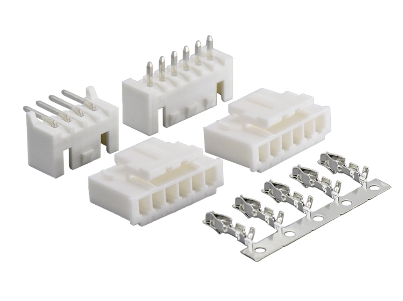

Commercial and military connectors have very big differences in structure, material, sealing and other levels:\

- Structure level military connectors often use double or even triple contact structure, insertion and removal life of more than 5000 times, contact resistance as low as 0.5mΩ, behind these parameters is several times more than the civilian materials and process costs.

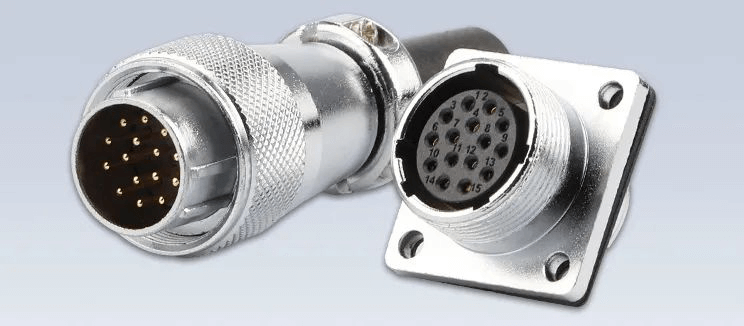

- Materials level modern military connectors have been titanium alloy, carbon fiber composite materials to gradually replace the traditional metal, in the weight reduction of 30% at the same time to enhance the ability of anti-electromagnetic interference; and such as polyimide (PI) insulation materials can be maintained at high temperatures of 250 ° C to maintain the stability of the performance of the on-board equipment from the impact of the engine heat flow.

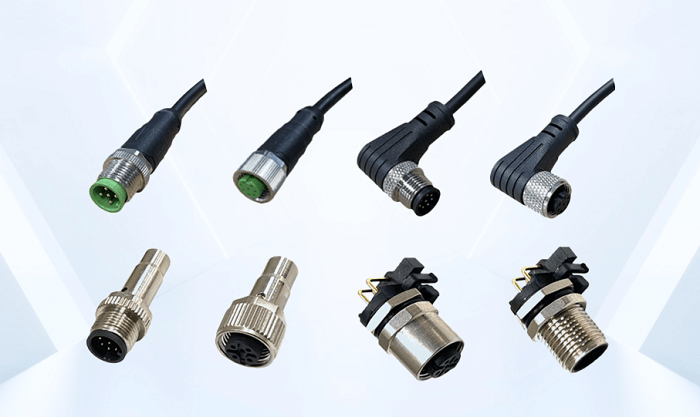

- Sealing technology is through the O-ring, gel potting and metal welding triple protection, combined with nano-scale surface treatment process, modern military connectors can achieve IP69K protection level, even in the deep sea 200 meters pressure or desert sandstorms can still maintain airtight.

The same military connectors have different characteristics in different applications:

- Aerospace: Lightweight hollow pins with floating structure to cope with high overload deformation in fighter jets.

- Armored Vehicles: Dust caps and triple redundant contact design for desert battlefield sandstorm environments.

- Naval equipment: IP69K protection level ensures zero signal loss under high pressure in deep sea.

Take XX highland UAV as an example, due to the misuse of a certain connector, the signal was intermittent in low temperature and low pressure environment, which eventually led to the failure of reconnaissance mission. Such lessons have given birth to the mandatory requirements of military standards – such as the U.S. military standard MIL-DTL-38999 series, which not only stipulates that the connector needs to pass 67 tests such as vibration, humidity, heat, mold, etc., but also requires the full traceability from the raw materials traceability to the production lot number.

With the rapid development of industry, application scenarios and requirements are becoming more and more demanding, military connectors have come into the public eye. The technical integration of industrial and military connectors, the essence of the reliability of the demand for upgrading and the expansion of extreme scenarios of the common role. When the wind turbine in the hurricane continued to generate electricity, when the chemical robot through the gas leakage site operations, when the plateau photovoltaic panels in the blizzard transmission of data – behind these industrial miracles, is a battlefield-proven “connector heart” in the strong beat. This kind of collaborative innovation across fields not only reshapes the value chain of high-end manufacturing, but also predicts the ultimate law of “reliability is core competitiveness” in future industrial competition.