Why DeepSeek will lead the industrial connector design revolution

Under the wave of Industry 4.0 and Artificial Intelligence (AI), industrial connectors, as the “nerve hub” of equipment interconnection, are undergoing a transformation from traditional hardware to intelligent carriers. With the breakthroughs of domestic large models such as DeepSeek in technology open source and cost reduction and efficiency, the design, manufacturing and application scenarios of industrial connectors are given new possibilities.

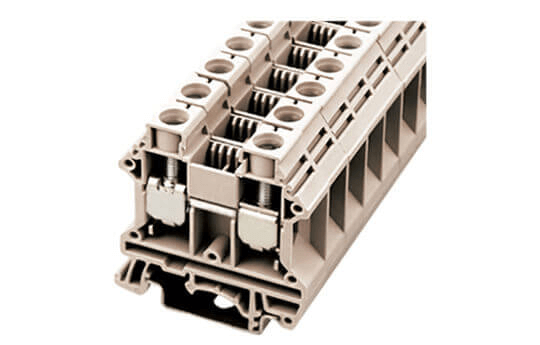

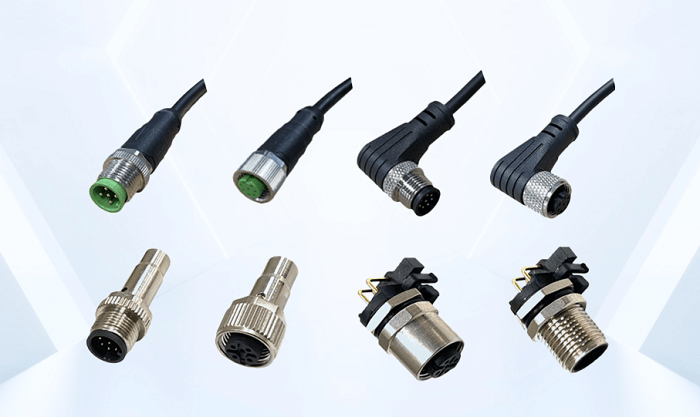

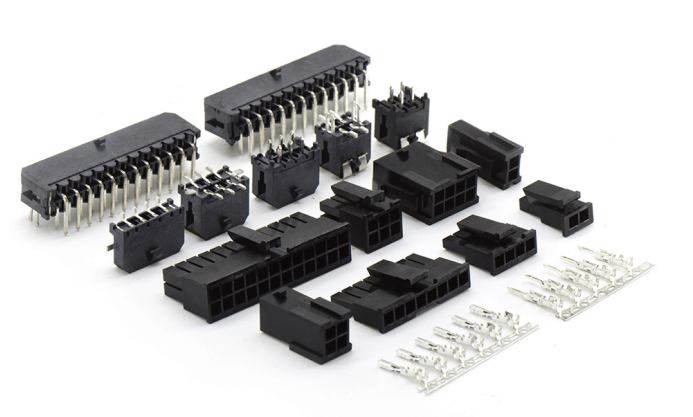

As we all know, the core function of industrial connectors is to ensure the stable transmission of signals, power and data, and its performance directly determines the reliability of the intelligent manufacturing system. Traditional design relies on experience and trial and error, while AI technology realizes a breakthrough through a new path:

1. Parameter optimization and simulation

AI algorithms can automatically optimize the structural parameters of connectors (e.g., contact part elasticity, insulation material selection) based on historical data and physical models. For example, signal attenuation in extreme environments can be simulated by Generative Adversarial Network (GAN) to improve the connector’s anti-interference capability.

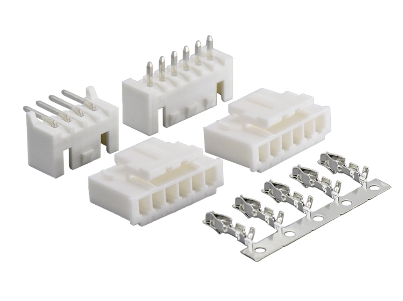

2. Multi-modal design collaboration

DeepSeek and other large models support cross-modal parsing of text, images and code, which can accelerate the conversion process of connectors from design drawings to production code. For example, an automation manufacturer uses AI to generate 3D models directly from engineers’ hand-drawn sketches for printing and development, shortening the development cycle by 40%.

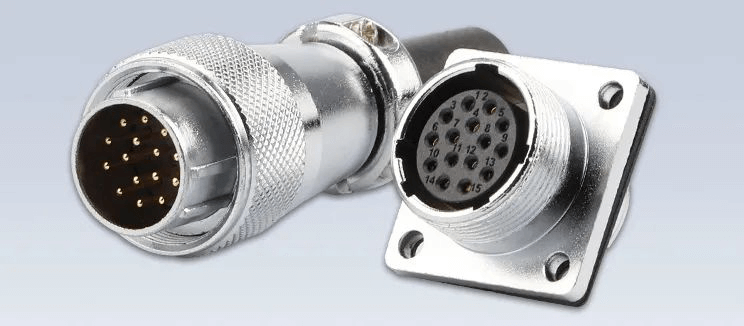

3. Material Innovation Prediction

AI combined with quantum computing can predict the conductivity and durability of new alloys or composites, promoting the application of connectors in high-temperature, high-pressure scenarios. For example, AVIC photoelectric development of high-temperature connectors have been adapted to aerospace extreme environments, the material screening process relies on AI simulation experiments, the results of scientific research is used to feed the R & D and manufacturing of industrial connectors.

Conclusion

The integration of industrial connectors and AI is not only the inevitable technology iteration, but also the core driving force of the reconstruction of the intelligent manufacturing system. With DeepSeek and other large domestic models in the open source ecology, cost control and scene landing breakthroughs, industrial connectors will be transformed from “invisible hero” to “intelligent pioneer”, promoting the global manufacturing industry to the efficient, reliable and sustainable future